WWTU development history.

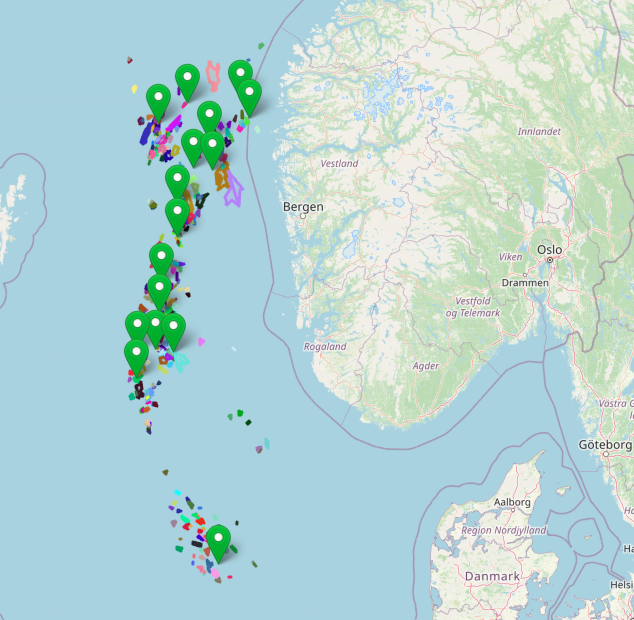

The first mechanical wastewater treatment unit for the completion phase in the North Sea was installed by OTS A/S onboard the Transocean Searcher operated by Statoil on the Åsgard field in early 2001. The idea was to come up with some mechanical separation to replace the flocculation and filtration process with no added chemicals.

By the end of the year 2001 OTS A/S was nominated for the chief executives HSE prize for 2001 in the Statoil system for the wastewater treatment unit processes.

During the following years OTS continued to improve the wastewater treatment process system by installing a fully complete wastewater treatment unit in the company’s wash bay area in Tananger to test and to optimize the system with different fluids. All internal washing and cleaning wastewater have since then passed through this effective treatment process providing valuable results.

The experience gained from the wash bay was transferred to our engineering department and implemented into the continued development of new offshore treatment units.

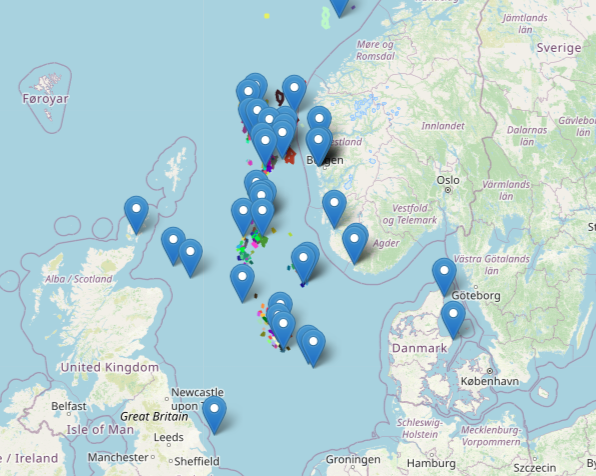

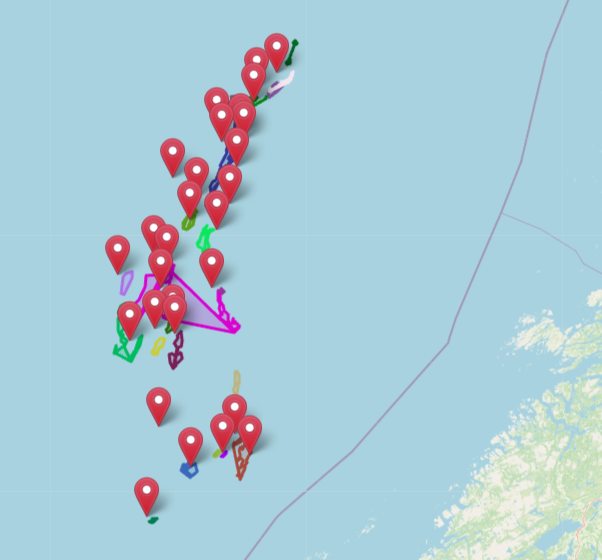

In 2009 OTS started to produce the new generation wastewater treatment units for the Norwegian offshore marked. The OTS treatment units have a well proven track record in the North Sea and elsewhere around the world.

The following years OTS has continued to optimize its sustainable wastewater treatment plants and in 2021 resulting in a benchmark product supreme to the oil & gas industry worldwide. Capacities more than 20m3 per hour. OTS prides itself with highly experienced personnel and equipment with a firm focus on the environment.

About wastewater treatment, wastewater treatment is a process used to remove contaminants from wastewater and convert it into an effluent that can be returned to the water cycle with no impact to the environment or reused for various purposes (called water reclamation). The treatment process takes place in a wastewater treatment unit (WWTU), pollutants in wastewater are removed, converted, or broken down during the treatment process. OTS continues to develop state of the art systems for a better environment.

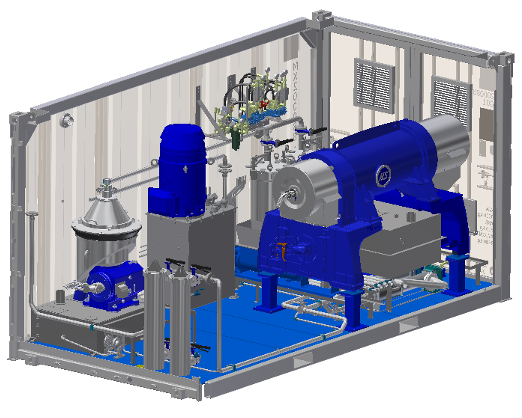

The OTS Wastewater Treatment unit is capable of processing OBM slop water, oil-contaminated brines, oil contaminated water and surface-generated water. The mechanical separation system generates three distinct waste streams: solids, oil, and water.

The oil is collected, and the clean water is discharged in accordance with local permits. Any minimum amounts of solids are contained for further treatment if required.

- Small footprint, one lift for installation

- Short installation time

- Significant reduction on total cost

- Capacity up to 20 m3 / hour

- No additives

- Oil in discharge water below 5 ppm

- No chemicals added

- Packaged in one 20 ft container

About OTS:

OTS is a privately owned company, established in Stavanger in 2001, which has progressively built-up knowledge through experience in the rental and service area for the oil and gas industry. We are a supplier of waste-treatment equipment, cuttings & fluids handling and treatment, well services pumps, rig/pit cleaning etc.

Our head office is in Stavanger, offices in Australia and UK. We have working partnerships in, US, Argentina, Denmark, Saudi Arabia, Oman and Tunisia. OTS offers modern workshop facilities for service and construction work. OTS is member of a larger privately owned group of companies, including but not limited to: Steel fabrication, Offshore Rig maintenance facilities, Well service tools, and more.

For more detailed information see https://www.youtube.com/watch?v=z70McEFHpbU&t=1s

or contact us for a visit and demonstration.

OTS Onsite Treatment Services AS – Norsea base building 104, 4056 Tananger Norway www.ots.as