A Russian oil and gas equipment manufacturing company is interested in the Norwegian market

Recently, Russian companies have been being actively interested in the possibility of export delivery in the field of oil and gas engineering. Today, we will tell you about a Russian enterprise Next Trade that is ready to export to Norway unique equipment that can be operated in conditions of high pressure, corrosive environments and low temperatures and is already stayed in service at Gazprom.

Despite the difficult situation in the global economy due to the coronavirus pandemic COVID-19 pandemic, 2020 was a record year for Russia in terms of non-resource non-energy exports. Russian Export Centre reported in February 2021 that in 2020 the export volume of non-resource non-energy has reached 161,3 billion US dollars in comparison with 155,1 billion US dollars in 2019.

In 2020 Russian non-resource non-energy export consists of:

-20,8% of metal products

-17,7% of mechanical engineering products

-17,3% of foodstuff

-16% of chemical commodities

The biggest part of Russian non-resource non-energy commodities was exported to China (for an amount of 16,369 billion US dollars), Kazakhstan (for an amount of 12.284 billion US dollars), Belarus (for an amount of 9.368 billion US dollars), Turkey (for an amount of 8.148 billion US dollars) and the Netherlands (for an amount of 6.237 billion US dollars).

Russia traditionally exports oil and gas equipment to India, USA, Germany, China, UK, United Arab Emirates.

As the Ministry of Energy points out, Russian can offer technologies and equipment for transporting gas and oil, drilling directional and horizontal and Multi-branch wells.

In March 2015, the Ministry of Industry and Trade of the Russian Federation approved a five-year development plan for the oil and gasmechanical engineering industry, which is being successfully implemented. Now every second unity of oil and gas equipmenton the Russian market is made in Russia, although only five years ago Russian oil and gas industry was heavily dependent on imported equipment.According to the Ministry of Industry and Trade of the Russian Federation, by 2024 Russia is planning to invest more than 334 million euro in support of domestic oil and gas engineering.

Tointroduce Russian equipment on international market the Ministry of industry and trade of the Russian Federation deals export issues of Russian commodities as well as cooperates with the international companies on utilization Russian industry standards for carry out international projects.

Russian manufacturers of oil and gas equipment are also actively presenting their products on international markets, as they are interested in developing business and external relations.

Тells Sergey Davydov, production director of the diversified group of companies Next Trade.

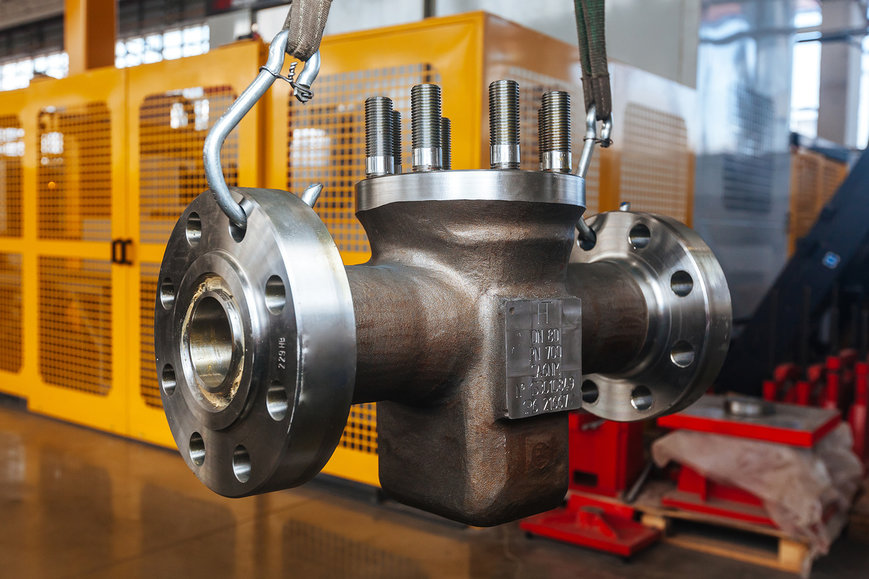

– The diversified group of companies «Next Trade» has been on the Russianoil and gas market for over 20 years.We manufacture equipment able to operate in gas fields inconditions of dangerous aggressive environments, some of which no more Russian company can manufacture-control and anti-surge valves,shut-off valves.

The company’s production base is located in Voronezh, a large industrial and scientific city in Central Russia. Voronezh is home to over 1 million inhabitants. Historically, a large number of knowledge-intensive manufacturing enterprises have been concentrated here. In recent years, Russia has been actively integrating enterprises into industrial clusters for efficient cooperation in solving production tasks.

The largest production cluster in the Voronezh region is the cluster of oil, gas and chemical equipment manufacturers.

It is a structure comprising 28 branch companies and is capable of realising the entire production cycle of technological equipment: аrom research and development to the manufacture, supply and servicing of equipment for the oil, gas, chemicalindustry and nuclear industry. Cluster members produce equipment for oil and gas production, transportation and recycling, such as control stations for fountain valves (also installed on offshore platforms), highly efficient heat-exchange and separation equipment, stainless steel pipes for main pipelines, shut-off and control valves, coiled tubing units, pumping equipment, etc.

In addition to manufacturing enterprises, the cluster infrastructure includes: a technology park, universities, project organisations, engineering and service companies, banks, i.e. organisations that ensure the development of the industrial cluster.

The total production volume of cluster members exceeds 222 million euros per year. The main consumers of the cluster’s products are large Russian businesses: «Gazprom (the Russian equivalent of Statoil), Rosneft, LUKOIL, NOVATEK, Sibur Holding, etc.

Yesterday and today – the history of NextTrade

– Next Trade, a diversified group of companies, is one of the leading companies in the cluster of producers of oil, gas and chemical equipment in the Voronezh region.

Next Trade is a group of companies united by one business mission – an anchor company specialising in metalworking, a foundry and an engineering office.

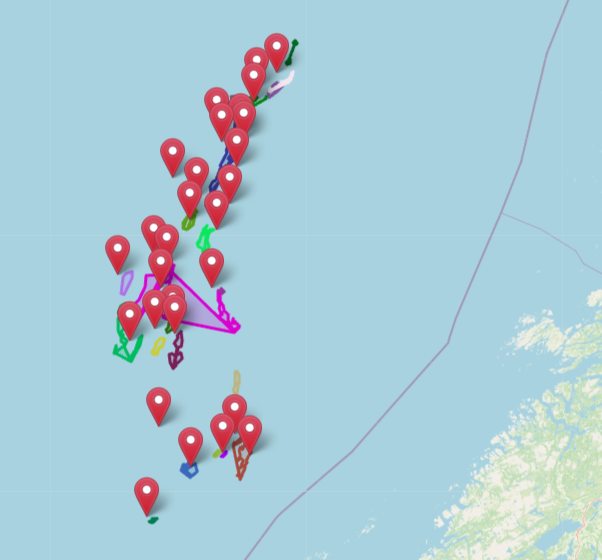

We manufacture and supply equipment to PJSC Gazprom’s fields, and our equipment is particularly in demand in Siberia and the Far North.

Back in 1999 we started out as a small company engaged in design engineering, repair and maintenance of imported equipment, mainly of Dutch origin, which was operated at Gazprom fields.

Lateracquired experience allowed the company to start its own production of anti-surge control valves and shut-off valves, for fields with high reservoir pressure (up to 700 bar).

Now the equipment manufactured by Next Trade replaces equipment made in Holland, the USA and France in Russia, and the enterprise has an area of 3000 sq. and more than 80 employees.

Long-term experience of the enterprise, high qualification of our engineers and employees, as well as an individual approach to the needs of each customer allows Next Trade to provide high quality products and services. It is сommonly accepted that technology and people are central to a successful business. Therefore, we are constantly expanding our fleet of equipment and educating workers and engineering personnel in accordance with international standards.

NextTrade has a number of its own patented engineering project of anti-surge equipment, which has been in operation for many years at Astrakhan UGS in high-pressure and corrosive environments conditions. In 2020 the Next Trade anti-surge valve was successfully tested at Gazprom’s Nadym field, confirming its functionality in the harsh conditions of the Far North.

NEXT TRADE PRODUCTS

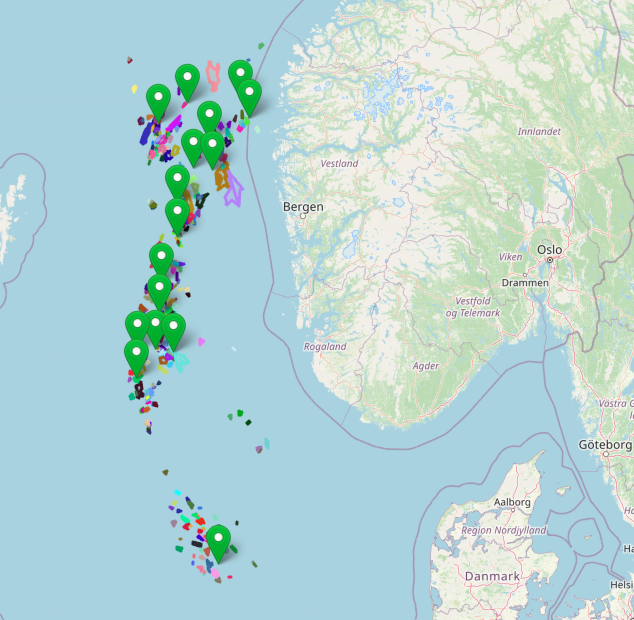

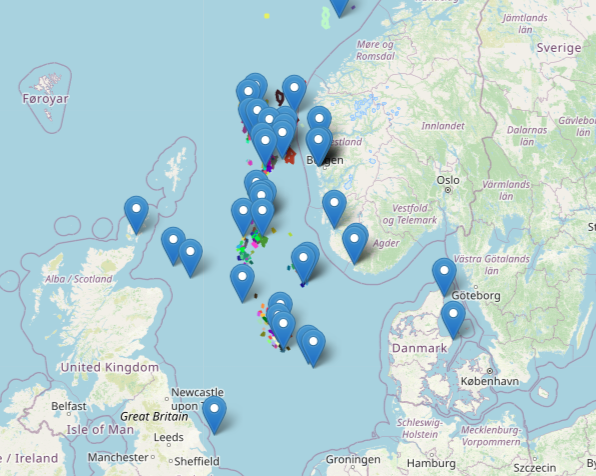

– The Next Trade Group of Companies is ready to offer the Norwegian oil and gas market equipment that can be operated under high pressure conditions:

– Control valves and anti-surge valves – analogue of Mokveldvalves;

– Wedge gate valves – analog of the products of Roforge, UFR, LOG;

– Needle valves – analogue of Swegelock products;

– Slide gate valves – analogue of Cameron, FMC, Malbranqua products.

– Components for oil and gas complex equipment, including non-standard equipment used at operating pressures up to 70 MPa in conditions of increased content of H 2 S, CO 2 with a mass fraction up to 25%.

Products supplied and works performed have the necessary approvals and are produced in accordance with API, ANSI, ASME, EN, MSS, NACE requirements. The presence of a foundry allows the company to control the full production cycle of the manufactured oil and gas equipment.

The company own stand for pneumohydraulic testing of pipeline valves is certified for pressure up to 115 MPa (1150 kg/cm2). The company’s quality management system is certified by TUV according to ISO 9001:2015.

THE COMPETITIVE ADVANTAGES OF NEXT TRADE PRODUCTS

– The first competitive advantage is the speed of order lead time. The usual manufacturing lead time for oil and gas equipment manufacturers is a year, but we have found a way to cut it in half. Next Trade produces standard parts in advance, and for a specific order all that is left is to assemble the product and check it. Unification of parts enables not only fast production but also fast and qualitative service.

The second equally important competitive advantage is product quality.

The finished product uses thermomechanical coating of the inner surfaces of body parts which extends the life of the equipment, technology for the processing of hard alloy, technology for special heat treatment which increases the resistance of the metal to corrosion and corrosive ambiente.

The third competitive advantage is real-time production control. In order to have full control of production, the company has launched the first phase of Russian IT hardware and software platform, which allows us to link all the production facilities into a single network and create a kind of a virtual digital twin of the plant which is easy to control. This way, we can ensure the highest possible quality of our products. We strive to make quality control a permanent element of technology at every stage of our production and to comply with international standards in this area.

ABOUT FUTURE PLANS

– We are interested in developing international cooperation and exportingof our products.The Norwegian oil and gas market seems particularly promising to us because the production of unique equipment dedicated to operate under difficult environmental conditions is a speciality of our company, proven by many years of experience and contracts with leading companies in the Russian oil and gas market. Now our goal is international markets. Exporting not only equipment but also technology is important to us.

Our countries are connected by long-term partnership in many spheres. It is a historical fact and it is objective. Temporary difficulties in international cooperation can hardly be seen as a serious limitation for constructive exchange of experience. For our part, we are fully open and ready to cooperate. At any time, we are happy to welcome partners from both Norway and other countries, to showcase our production and share information about promising developments. We believe that such cooperation benefits everyone involved and opens up new development opportunities.

We will be glad to cooperate with new partners!

Any questions you are interested in can be asked by e-mail : mail@nt-group.ru

Learn more about technical characteristics of Next Trade products on our web-site nt-group.ru